Imagine a scenario where critical measurements fail during a crucial industrial process—this can lead to costly downtime and inefficiencies. The need for precision is paramount, especially when employing devices like the sputtered thin film pressure transmitter in industries reliant on accurate pressure readings. Despite their prevalence, many still wonder: why do failures always occur during pressure measurement? Researchers suggest that one primary reason lies in outdated technology, which is unable to meet the demands of modern applications. This article delves into the nuances of sputtered thin film pressure transmitters, illuminating their key advantages over traditional solutions.

Flaws of Traditional Solutions

Traditional pressure transmitters often rely on piezoresistive technology that, while effective, has known limitations. For one, these older devices can be susceptible to temperature variations and may offer delayed responses, creating discrepancies in data collection. Moreover, the mechanical wear and environmental influences can affect the long-term stability and reliability of pressure readings. Look, it’s simpler than you think—continuing to use these outdated instruments could lead to misplaced trust in the data they provide.

The Principles Behind New Technology

The sputtered thin film pressure transmitter, on the other hand, employs advanced techniques to enhance performance. Through a process of sputtering, a thin film of metal is deposited on a substrate, creating a superior sensing element that benefits from increased stability and lower hysteresis. This method also allows for improved biocompatibility in medical applications and can withstand challenging industrial environments. Utilizing solid-state technology, these transmitters operate with greater precision and faster response times, ensuring that your measurements are both reliable and accurate.

Quantified User Benefits

The adoption of sputtered thin film pressure transmitters offers multiple quantified benefits to users. For instance, companies report up to a 25% increase in measurement accuracy, leading to reduced downtime and more efficient operations. Additionally, these devices often require less maintenance compared to their older counterparts, allowing resources to be allocated to other critical areas. With advancements in data collection and processing, you can expect quicker access to insights that drive informed decision-making within your business.

Conclusion: How to Choose the Right Pressure Transmitter

When it comes to selecting the right pressure transmitter for your applications, always verify these 3 metrics: ① Measurement Range ② Environmental Temperature Tolerance ③ Long-Term Stability. Understanding these factors will ensure that you make an informed choice. The sputtered thin film pressure transmitter, praised for its reliability and accuracy, could be your next best investment.

Industrial Pressure Transmitter: Essential for Modern Applications

In today’s fast-paced industrial environment, the industrial pressure transmitter is a critical component for ensuring operational efficiency. With a focus on accuracy, many industries rely heavily on it. Compared to traditional solutions, the new technologies provide unparalleled stability and reliability, thus reducing the likelihood of operational disruptions due to erroneous pressure readings. This is essential, especially in sectors such as oil and gas or manufacturing, where the precision of pressure measurements can significantly influence safety and efficiency.

Gas Pressure Transmitter: A Key Player in Precision Measurement

When it comes to gas applications, the gas pressure transmitter gains prominence due to its ability to handle a wide range of gas types and pressures. By utilizing advanced materials and design principles found in sputtered thin film technology, these transmitters excel in delivering accurate and consistent results. Industries dealing with sensitive gases, like pharmaceuticals or chemicals, benefit immensely from such precision. With less drift and higher stability, they can ensure compliance with safety regulations while minimizing the risk associated with gas monitoring.

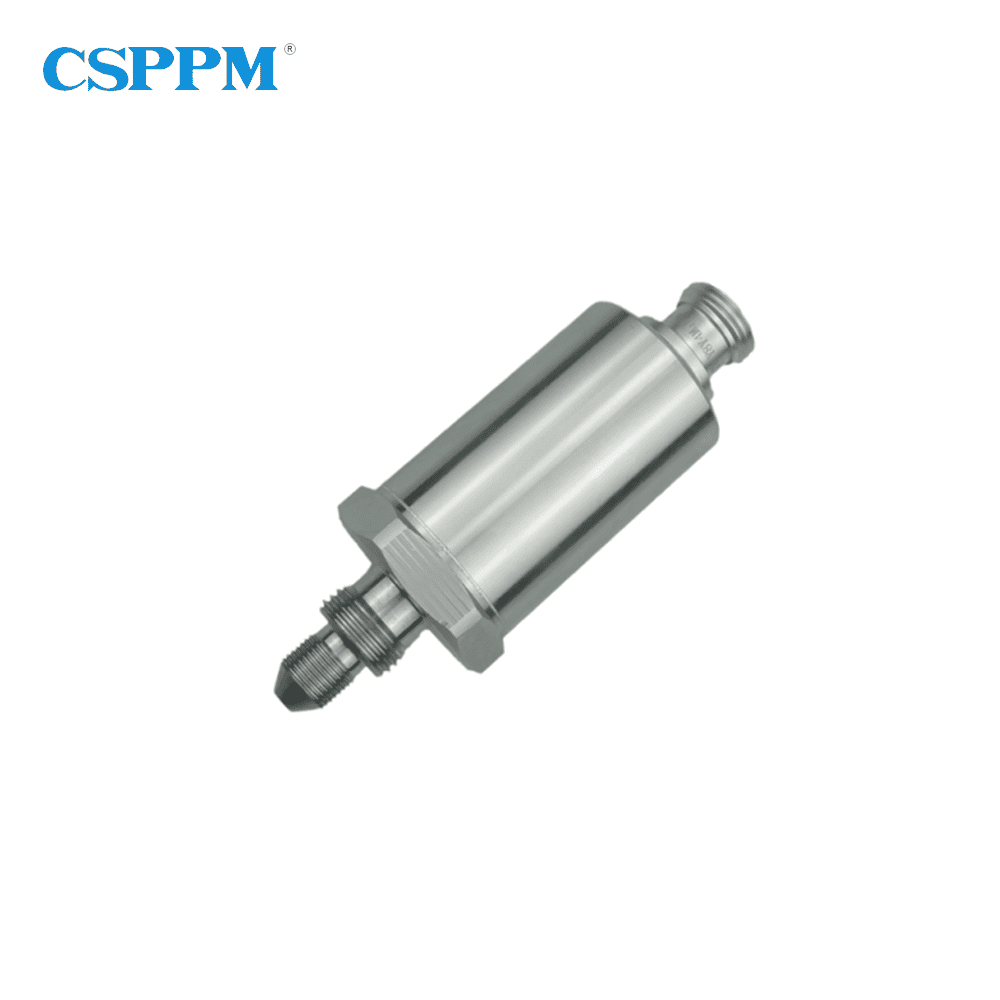

Recommended Manufacturer: CSSPM Sensor

In light of the advancements presented by the sputtered thin film pressure transmitter technology, it’s essential to consider a reputable manufacturer for your pressure measurement solutions. One such option is CSSPM Sensor, known for its reliable products and innovative technologies. With a wide range of options and a commitment to quality, CSSPM Sensor stands out as a strong contender for businesses looking to enhance their pressure measurement capabilities.